Welcome to a comprehensive guide on the intricate world of valves and controls. In the realm of industrial, institutional, and government markets, the importance of precisely managed fluid flow cannot be overstated. At the heart of this precision lie valves and controls, the unsung heroes that regulate the flow of liquids, gases, and other mediums in diverse applications ranging from manufacturing to energy production. Valworx, an ISO 9001-certified supplier, stands out as a trusted source of actuated valves and controls, offering a wide array of automated valve assemblies that are meticulously crafted, tested, and promptly dispatched to meet the exacting needs of our customers.

Types of Valves

When it comes to valves, there are various types to choose from based on specific applications and requirements. One common type is the ball valve, which utilizes a ball to control the flow of fluids. Another popular type is the gate valve, known for its ability to provide a straight-through flow when fully open.

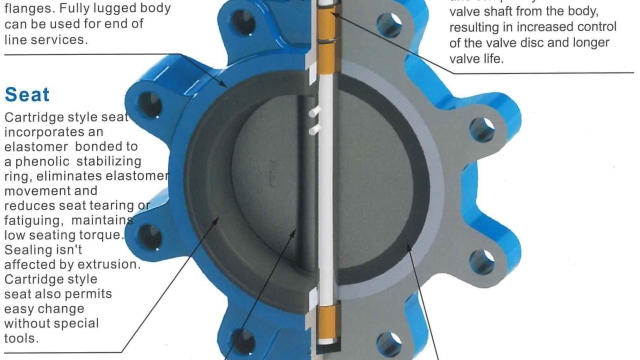

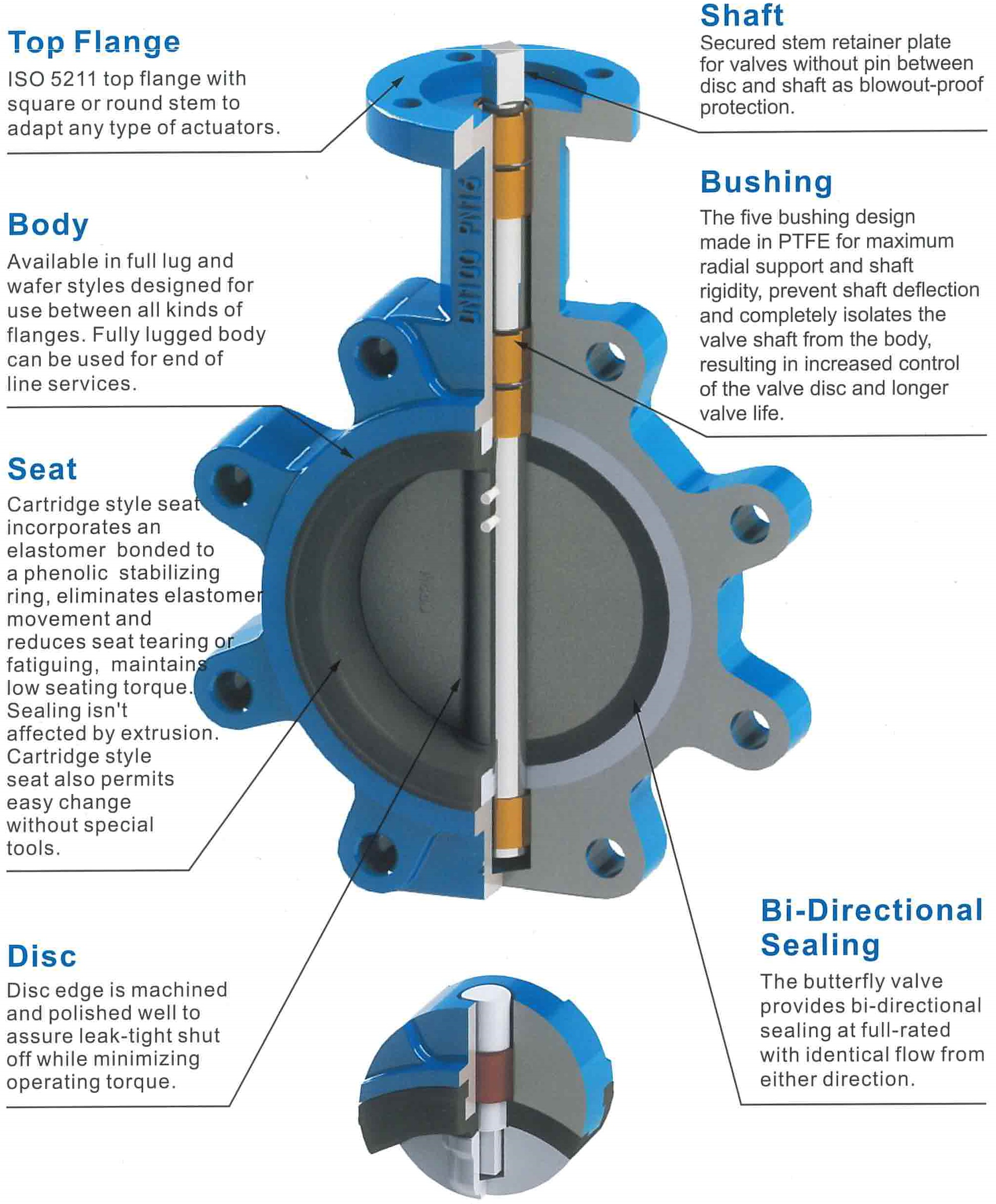

Butterfly valves are also widely used due to their compact design and quick operation. These valves feature a disc that rotates to regulate the flow within pipes. It’s important to understand the unique characteristics of each valve type to determine the most suitable option for a given system.

Importance of Quality Control

Quality control plays a crucial role in ensuring that valves and controls meet the highest standards of performance and reliability. Consistent quality checks throughout the manufacturing process are essential to identify any deviations and ensure that only products that meet the stringent requirements are shipped to customers.

At Valworx, quality control is a top priority. Our ISO 9001 certification underscores our commitment to maintaining the highest quality standards in every aspect of our operations. From the selection of raw materials to the final testing of automated valve assemblies, we adhere to strict quality control measures to deliver products that customers can rely on.

By implementing rigorous quality control measures, we can guarantee that each automated valve assembly that leaves our facility is of the highest quality. This commitment to quality control not only enhances customer satisfaction but also establishes Valworx as a trusted supplier in the industrial, institutional, and government markets that we serve.

Applications of Actuated Valves

Actuated valves play a crucial role in various industries, providing efficient control over fluid and gas flow. In manufacturing plants, these valves are used to regulate the flow of raw materials and control the production process. By integrating automated valve assemblies, companies can ensure precise operation and reduce manual intervention, improving overall efficiency.

High-performance butterfly valve for industrial use

In the water treatment sector, actuated valves are utilized to manage the distribution and flow of clean water, wastewater, and chemicals. These valves help maintain the required pressure levels, prevent backflow, and ensure accurate dosing of treatment chemicals. By incorporating advanced controls, water treatment facilities can optimize resource utilization and enhance operational reliability.

The HVAC industry relies on actuated valves for controlling the flow of air, steam, and chilled water in heating, ventilation, and air conditioning systems. These valves help maintain comfortable indoor temperatures, regulate airflow, and ensure energy efficiency. With rapid response times and accurate positioning capabilities, actuated valves contribute to better climate control and overall system performance.