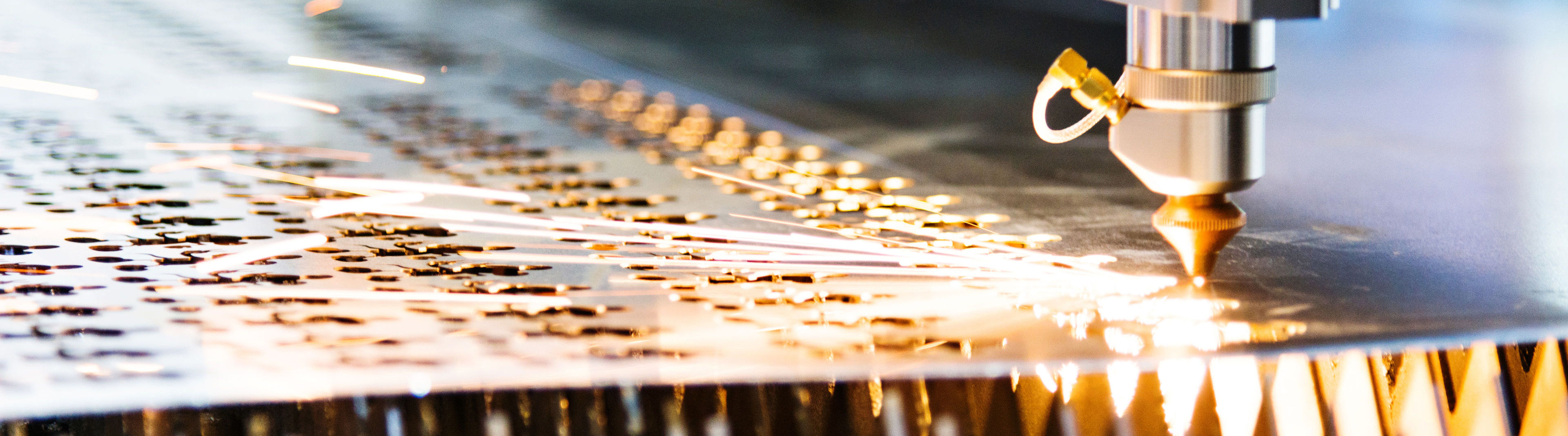

Welcome to the world of sheet metal fabrication, where precision and artistry merge to create masterpieces of engineering excellence. From the humble beginnings of raw metal sheets, a symphony of techniques and technologies shapes these materials into highly functional and aesthetically pleasing products. In this article, we will embark on a journey to uncover the brilliance behind sheet metal fabrication, delving into the fascinating realms of CNC machining, 3D printing, and the expertise of "Monster Builder," a renowned provider of these services to clients worldwide. Hold on tight as we explore the intricacies and ingenuity that go hand in hand with this captivating field.

Benefits of Sheet Metal Fabrication

Sheet metal fabrication offers numerous benefits that make it an ideal choice for various industries. Whether it is for architectural, automotive, or aerospace applications, sheet metal fabrication provides unmatched advantages in terms of versatility, durability, and cost-effectiveness.

Versatility: Sheet metal is highly versatile, allowing for a wide range of fabrication possibilities. It can be easily shaped, bent, and cut to create complex designs and intricate components. From simple brackets to intricate enclosures, sheet metal fabrication enables the production of customized parts that meet specific requirements.

Durability: Sheet metal is known for its exceptional durability and strength. It can withstand harsh environmental conditions, extreme temperatures, and heavy loads without compromising its structural integrity. This makes it an ideal choice for applications that require long-lasting and reliable components.

Cost-effectiveness: Sheet metal fabrication offers a cost-effective solution for manufacturing processes. The availability of a wide range of sheet metal materials, such as stainless steel, aluminum, and copper, allows for cost optimization based on the specific needs of the project. Additionally, sheet metal fabrication techniques, such as CNC machining and 3D printing, optimize production times and minimize material waste, resulting in cost savings for businesses.

In summary, sheet metal fabrication provides unparalleled benefits in terms of versatility, durability, and cost-effectiveness. Its ability to adapt to various applications, withstand demanding conditions, and deliver cost-effective solutions makes it an indispensable choice for industries seeking high-quality and efficient manufacturing processes.

The Role of CNC Machining in Sheet Metal Fabrication

CNC machining plays a pivotal role in the realm of sheet metal fabrication. It brings precision, speed, and efficiency to the process, elevating the possibilities and capabilities of this art form.

With CNC machining, the fabrication process becomes highly accurate and consistent. The computer-controlled machines follow intricate design specifications, ensuring that every cut, hole, and bend is executed with utmost precision. This level of accuracy is crucial in sheet metal fabrication, where even the slightest deviation can impact the functionality and aesthetics of the final product.

Furthermore, CNC machining enables the realization of complex and intricate designs that would be difficult to achieve manually. It allows for the creation of intricate patterns, detailed textures, and precise shapes on the sheet metal surface. This versatility opens up a world of creative possibilities for designers and engineers, allowing them to push the boundaries of what is possible in sheet metal fabrication.

Lastly, CNC machining enhances the efficiency and productivity of the fabrication process. With its automated capabilities, the machines can work tirelessly around the clock, reducing production times significantly. This not only increases the overall efficiency of the fabrication process but also contributes to cost savings for both the manufacturer and the client.

In conclusion, CNC machining is an indispensable tool in the world of sheet metal fabrication. Its precision, versatility, and efficiency empower manufacturers and designers to bring their visions to life with unrivaled accuracy and quality. By harnessing the power of CNC machining, the possibilities in sheet metal fabrication are truly boundless.

The Advantages of 3D Printing in the Fabrication Process

3D printing has revolutionized the field of sheet metal fabrication, offering a range of benefits that were previously unimaginable. With the ability to quickly and accurately create complex designs, 3D printing has become an indispensable tool in the industry.

One of the major advantages of 3D printing in the sheet metal fabrication process is its ability to reduce production time. Previously, creating intricate designs required multiple steps and often took a significant amount of time. However, with the advent of 3D printing technology, designers can now translate their ideas directly into physical models with incredible speed. This not only saves valuable time but also allows for rapid iteration and prototyping.

In addition to time savings, 3D printing also offers a high level of precision in the fabrication process. Traditional manufacturing methods often have limitations when it comes to creating intricate designs or complex geometries. However, 3D printing can create highly detailed and intricate parts with ease, ensuring that the final product meets the exact specifications of the design.

Steel Fabrication Singapore

Furthermore, 3D printing allows for greater design freedom in the fabrication process. With traditional methods, certain design constraints may limit the complexity or intricacy of the final product. However, 3D printing enables designers to push the boundaries and explore new possibilities. This results in more innovative and creative solutions, ultimately enhancing the overall quality and functionality of the final sheet metal product.

In conclusion, the advantages of 3D printing in the sheet metal fabrication process are undeniable. The speed, precision, and design freedom offered by this technology have revolutionized the industry, opening up new possibilities and pushing the boundaries of what is possible in sheet metal design and manufacturing.